Building structures, especially older ones, gradually lose their original load-bearing properties. This may result from material degradation or changes in how the facility is used. Modern repair technologies are increasingly applied to restore structural strength without altering the geometry of the building. One of the most effective development directions in this field involves solutions based on mixed materials.

Effective support for load-bearing elements

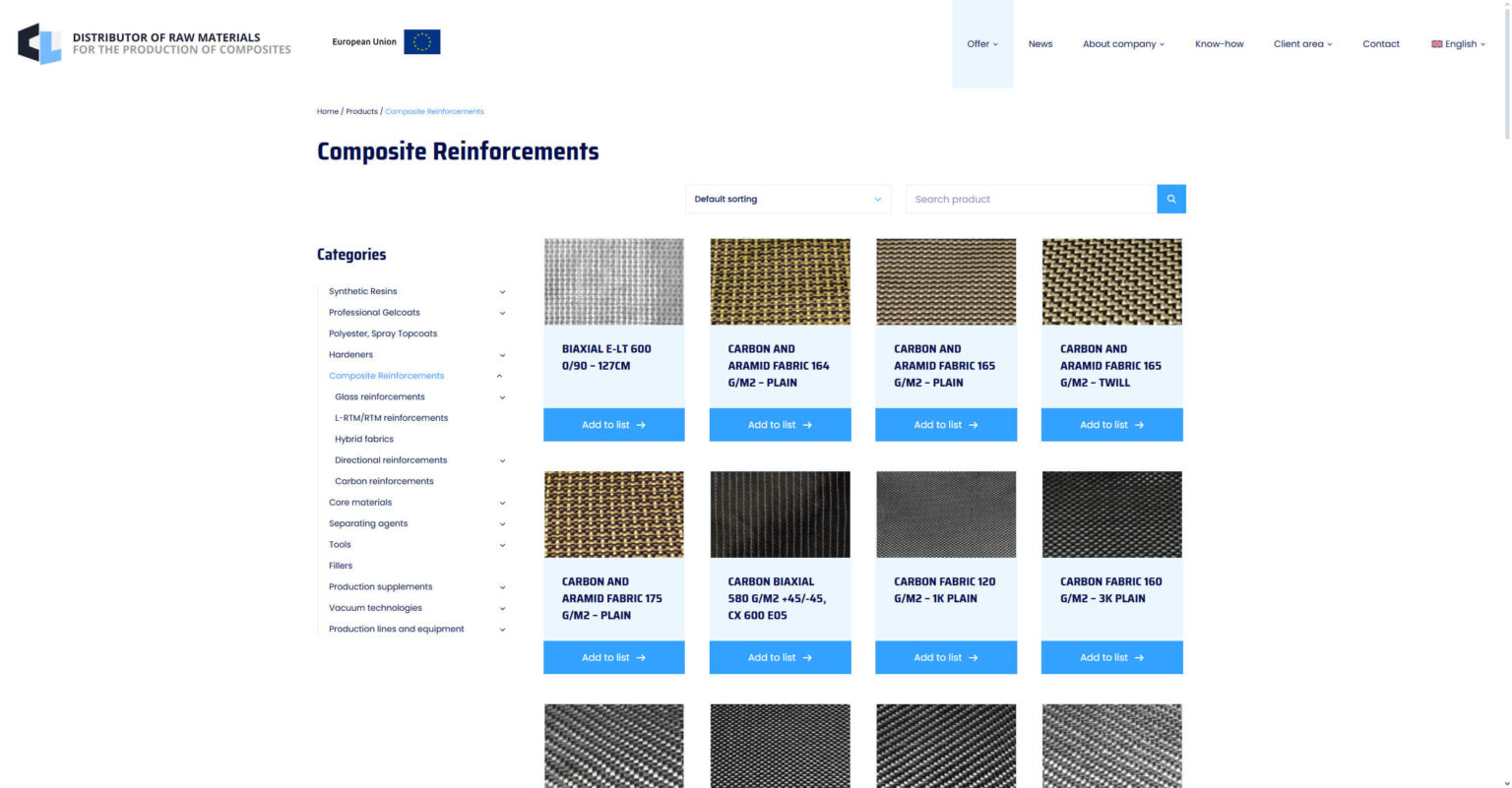

In reinforced concrete, steel or masonry structures, it is crucial to restore adequate load capacity while adding as little extra weight as possible. This is where composite reinforcements come into play. Their high strength-to-weight ratio allows an increase in load-carrying capacity without overstressing the structure. These materials also show strong resistance to corrosion and chemical exposure, which is essential in construction environments.

Applications in historic and operational buildings

When traditional repair methods are limited by structural or conservation constraints, a promising alternative can be found at c-l.eu/composite-reinforcements/. These C-L composite reinforcements offer flexible application on complex shapes without dismantling structural elements. The technology is particularly effective for buildings that must stay operational, as it avoids the need for long shutdown periods.

Minimal intervention, maximum effect

A key advantage provided by composite reinforcements is the absence of heavy supports or additional beams. Installation involves bonding carbon, glass or aramid fibre tapes or mats to the surface of the strengthened element using specialised resins. This reduces installation time and lowers logistical costs. It also avoids altering the interior aesthetics or the dimensions of the structure.

Resistance to time and environmental conditions

The durability of materials used in this technology is confirmed by numerous laboratory and field studies. Composite reinforcements maintain their properties over long periods, even under increased humidity or temperature fluctuations. For this reason, they can be used in industrial, bridge and residential structures. It is essential, however, that the design and application process be carried out by qualified specialists in accordance with relevant standards and technological procedures.

A modern approach to structural protection

Growing demands regarding building safety and durability mean that new technologies are increasingly becoming standard practice in structural engineering. Their effectiveness, low weight and resistance to environmental factors make them a practical alternative to traditional repair methods.

Economic efficiency in the long term

While the initial cost of advanced materials might seem higher than traditional methods, the overall project economy often favors modern solutions. Reduced labor hours, the elimination of heavy machinery on-site, and the lack of a need for extensive structural demolition significantly lower total investment costs.

Furthermore, the extended service life and minimal maintenance requirements of these systems ensure that the structural integrity is preserved for decades, providing a much higher return on investment compared to conventional steel-jacketing or concrete-thickening methods.

Precision in design and execution

The success of modern structural strengthening lies in the synergy between high-quality materials and precise engineering calculations. Every project requires an individual approach where the fiber orientation and resin properties are matched to the specific stress patterns of the building.

This level of customization allows for the “surgical” reinforcement of only the critical zones, avoiding unnecessary material use. As the industry moves toward more data-driven construction, the integration of these advanced systems with digital structural monitoring is becoming a standard for high-value infrastructure.